Land-based salmon still not investor-ready

March 30, 2016

By Brad Hicks

An analysis of the BC-based “Kuterra” project confirms that there is currently no sound business case to be made for rearing market-size Atlantic salmon on land.

An analysis of the BC-based “Kuterra” project confirms that there is currently no sound business case to be made for rearing market-size Atlantic salmon on land.The Salmon Aquaculture Innovation Fund at Tides Canada recently released its final report on the ‘Namgis First Nation’s land-based Atlantic salmon project on northern Vancouver Island in British Columbia.

A detailed analysis of the Tides’ report on the heavily subsidized “Kuterra” project confirms that at this time there is currently no sound business case to be made for rearing market-size Atlantic salmon on land.

However, before launching into an analysis of the Kuterra project it is important to acknowledge the hard work and commitment demonstrated by the employees and managers of Kuterra and the ‘Namgis First Nation. It is clear from the Tides’ reports that they have made an incredible effort getting to this stage and this article is not intended as a criticism of their efforts.

Land-based proponents

Some environmental groups, government agencies and First Nations continue to insist that land-based operations, like Kuterra, are economically viable and a successful alternative to net pens for commercial Atlantic salmon production. While Kuterra should be congratulated on their efforts with the project, their experiences to this point clearly demonstrate that they have been unable to achieve economic viability and therefore are unable to support a case that inspires investment on a scale needed to rear market-size Atlantic salmon in this type of system. Indeed, one of the strongest proponents for this venture, Dr Andrew Wright, commented at a workshop on rearing salmon on land in Virginia last fall that this system was not yet investor-ready.

Kuterra funding

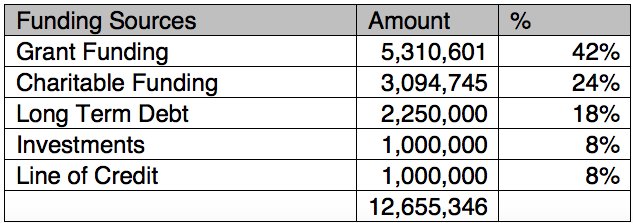

The project was funded primarily by Government of Canada grants and a large charitable donation by Tides Canada, using funds provided primarily from the US-based Gordon and Betty Moore Foundation. The remainder was a combination of contributed or borrowed capital by the ‘Namgis First Nation. Of the total project funding, $9 million was construction capital and $3.5 million were operational start-up funds.

Construction

The accompanying chart shows how the $9 million in construction costs were allocated.

The facility was constructed on forested land owned by the ‘Namgis First Nation and although costs associated with tree removal, levelling the construction area, drilling wells etc, are reflected in the costs, purchase of the land is not.

System Goal

The system was designed to produce 400 metric tons of harvested product per year (measured as whole fish, guts-removed, head-on) which equates to $22,630/metric tonne of production based on capital costs. This is approximately seven times more expensive than a comparable net pen facility. To date, this project is achieving a level of production equivalent to ~250 metic tonnes/year. If this level of production cannot be increased, capital costs would be roughly 12 times higher than the norm in the net pen industry.

Operational results

The report covers four production groups which have been harvested and another three groups growing in the system. Details are shown below:

March 13, October 13, January 14 and May 14 harvested; October 14 partial harvest; January 14 and April 15 pre-harvest.

The project reports provide a thorough analysis of commissioning issues and of the challenges experienced with each group. It is obvious from the details contained in the reports that the technology and process is neither robust nor dependable at this stage. The project managers have struggled with design and capacity elements as well as water quality. These challenges are in turn reflected in the production which is well below expectations.

Harvesting

Based on the Kuterra reports, weights have been dramatically lower than their targets (2.4 kegs versus 6 kgs targeted) and the norm for the farmed salmon industry (5.0 – 5.5 kgs). Low harvest weights are a function of slower-than-expected growth, higher maturation rates, increased mortality and rearing capacity constraints.

What’s more, it appears that quality has been variable. On average only 79% of the product harvested has been graded Premium. The norm within the net pen industry is 85% – 95%.

Nineteen percent of the volume produced in the first two years of production (48,000 kgs) was unsold in frozen inventory. Commentary in the report suggests this product is of inferior quality – primarily pale meat. It is unclear how this inventory is reflected in the financial statements. Notes indicate that costs and potential revenue associated with this product are not reflected in the unit costs and sales prices reported. It is also unclear as to whether this discounted inventory has been written down. Failure to write down this inventory will result in an understated cost of production.

Operational issues

As with most startup situations, the Kuterra facility has experienced significant technical and biological challenges over the past two years. Recirculating land-based systems are purported to eliminate pathogen risks and reduce mortality compared to net pen production. However, the data supplied to date shows much higher levels of mortality in this land-based system compared with mortality levels seen in salmon net pens.

In this type of system, it is also assumed that consistently higher rearing temperatures will enable faster growth and shorter production cycles. So far, the growth rates have actually been lower than experienced in net pens.

Maturation rates, which result in slower growth and downgraded product, have also been much higher in this land-based system than in conventional net pens. With these operational results it is not surprising that this facility is still financially unsuccessful.

Maturation

Atlantic salmon normally mature (the physical and metabolic changes to prepare for spawning) in their 3rd, 4th or 5th years. Salmon farmers typically use photoperiod lights to manipulate the response of the fish and delay maturation until at least the fourth year when 100% of the crop will have been harvested. Normally a net pen producer will see ~1 – 3% of the fish mature despite the photoperiod lighting. Maturing fish do not convert feed into red flesh. Rather, they convert feed into eggs and milt and after a certain stage, begin to catabolize their own flesh to become ready for spawning. The meat from maturing fish has low market value.

To date the Kuterra project has experienced high maturation rates among all of its harvested groups despite the use of photoperiod lights. Although there was an improvement from the first to second cohorts (0313 – 1013), the rates on the remaining completed groups may be consistent when factored for harvest size. Cohort 1014 is showing a low level of maturation but it is too early in its growth cycle to know for sure if the photoperiod adjustments will be successful in reducing the maturity rate.

The Freshwater Institute had similarly high maturation results with a trial of land-based production in 2013. A link to their report is included at the end of this article.

Fungus

Fungal infections are common during the freshwater (hatchery) phase of salmon farming and are normally controlled using salt or formalin. Fungus is not a concern in the marine environment. Management of fungal mortality using a combination of salt and formalin seems to have resulted in lower mortality for the current cohorts. Final mortality figures will not be available until these cohorts are harvested.

Cataracts

Cataracts are a significant problem and sampling indicates fish with cataracts are ~20% smaller than those without. The absence of cataracts in the first two cohorts may reflect a late recognition of this problem rather than an absence of the problem. Cataracts are occasionally seen in net pen reared salmon but at very low levels (likely below 1%). The pathogenesis of the cataracts is unknown. This is another problem that will need to be solved before this system will be functioning successfully.

Feeding

The accompanying graph shows the amount of feed available per week expressed as a percentage of the average weight of the fish in that week. It is a common metric for comparing feeding performance between groups with differing populations. The graph indicates the challenges experienced in determining the correct feed ration for each group. Particularly with the first three cohorts, there was considerable variability in feed response from week to week.

The data suggest (and the report commentary supports) that initial cohorts were significantly overfed. In a recirculating environment, uneaten nutrients can present enormous challenges for managing water chemistry. High rearing densities and turbidity leading to poor light penetration in the tanks can make it difficult to ensure that all feed is eaten. In a net pen environment, overfeeding is avoided through the use of underwater cameras and other feedback systems. Water clarity and light penetration in the marine environment is typically sufficient to make these systems consistently effective.

Growth

The graph below compares growth on a typical sea site to the average of the first seven cohorts in the Kuterra facility. When comparing the weekly data summaries to an existing net pen facility, the growth on a sea site is 25% faster and results in a harvest fish of 4.9 kgs (live weight) in 72 weeks versus a fish of 3.9 kgs (live weight) at Kuterra. Ambient temperatures are considerably lower in the net pen environment which goes against the belief that higher temperatures alone in a land-based system will lead to more rapid growth.

Energy Consumption

Energy is a major input for land-based farms. The Kuterra project consumed 597,120 kwh of electricity production for 250 tonnes, equal to $745 per metric tonne. Generating electricity for a similar size net pen farm would be equivalent to $50 – $60 per tonne.

Not Alone

There have been numerous failures for those attempting to grow market salmon in land-based systems. Going back to the early 1990s there was a large pump ashore operation called Hagensborg Resources in Nanaimo BC, which had several different operators over the years but all failed and millions of dollars were lost. Other notable failures for land-based growout salmon include Sweet Spring Salmon in Washington State and Hutterite-operated farms in Montana. There were also several land-based farms in eastern Canada and Denmark that ran into significant problems.

Conclusions

The production of farmed salmon from net pens has reached in excess of 2.4 million tonnes worldwide. However, at this time there are no long-lasting, profitable land-based systems for rearing market-sized Atlantic salmon.

Market salmon produced in these systems are simply still not economically competitive when compared to net-pen fish, a fact which will continue to make them unattractive for private sector investment.

— Brad Hicks

[To read the response from Kuterra to this article, please click here.]

Dr Brad Hicks has been working in the fish farming industry for over 40 years. He has raised six species on a commercial basis and helped pioneer the rearing of sablefish. He has been involved with fish farming operations throughout Canada, the US and Chile. He was the founding chairman of the Pacific Organic Seafood Association and a principal author of the Canadian Organic Aquaculture Standard. He is currently a partner in a privately held feed company in BC. Pertinent to this current discussion, Dr. Hicks was responsible for the decision to install the first land-based smolt rearing facility in British Columbia in the mid 1990s, and served as a member of the Technical Advisory Committee for Tides Canada on the Kuterra project. Dr. Hicks holds degrees in fish and wildlife biology BSc., pathology MSc and veterinary medicine DVM.

The information contained in this article is taken from a series of technical and financial reports issued by Kuterra and, in some cases, from net pen data available to the author. (A link to the Kuterra reports is below).

Link to Kuterra Reports

http://tidescanada.org/wp-content/uploads/2016/01/saif_workshops_reports_dec2015.pdf

Link to Freshwater Institute 2013 Land Based Salmon report:

http://www.conservationfund.org/images/projects/files/FI-ASF_Final-Report_March-20131.pdf

* * * * * * * *

A place for land-based systems

The first land-based system for rearing Atlantic salmon in British Columbia was installed 20 years ago. This facility was an earlier version of the current Kuterra system and it was used for rearing Atlantic salmon smolts, not market fish.

It was a successful operation and now most Atlantic salmon smolts are reared in land-based recirculating systems. These systems work well for rearing smolts because they are more efficient than flow-through freshwater systems where ambient water temperatures limit growth rates and overall hatchery production. Some public hatchery systems are also successfully using land-based systems to rear pacific salmon smolts for stocking.

Land-based systems have also been successful for a number of non-salmonid species. Tilapia (primarily for the live market), Barramundi, stripped bass, sturgeon and eels have been reared profitably in land-based systems. Going forward land-based systems will be refined and improved and will be suitable for rearing a variety of species. However, there will also be limits to their application and whether or not they can ever be developed to the point where they can competitively grow market-ready Atlantic salmon remains to be seen.