How Marine Harvest uses technology to lead the Blue Revolution

May 22, 2018

By Ruby Gonzalez

Marine Harvest has applied for development licenses to test semi-closed technology concepts as it continues to seek new and innovative solutions for the aquaculture industry.

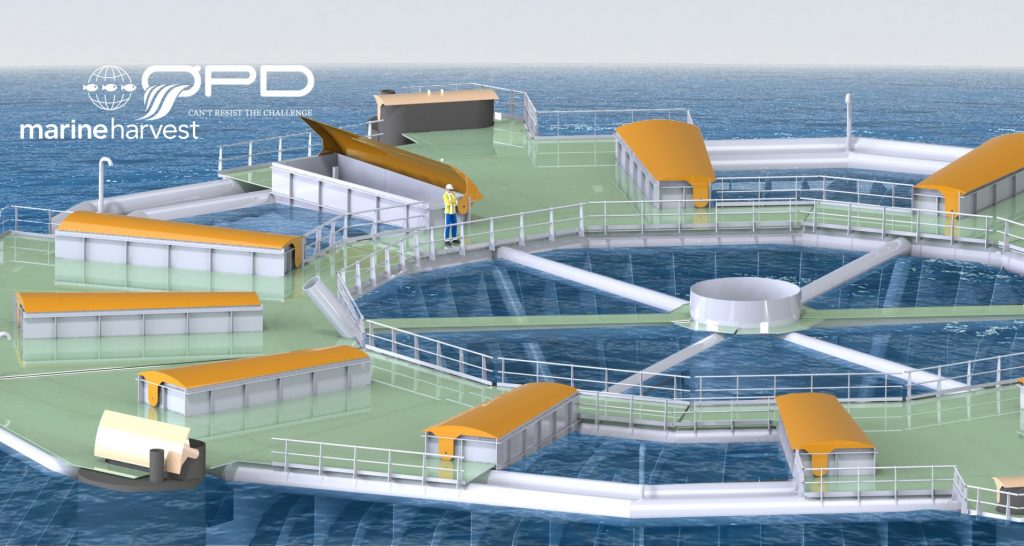

The “Donut” is one of the many technological solutions developed by Marine Harvest to improve fish quality and welfare. The company is seeking approval from Norwegian authorities to farm 5

The “Donut” is one of the many technological solutions developed by Marine Harvest to improve fish quality and welfare. The company is seeking approval from Norwegian authorities to farm 5 “Since the floating semi-closed technology is still very new, we are focusing on testing several different concepts, to be sure we select the best one, once the technology is taken to a larger scale,” Marine Harvest Group Manager for Freshwater and Closed Production Technology, Trond Rosten, told Aquaculture North America (ANA).

The Egg is a 20,000 m3 semi-closed farming system that has a capacity for a 1,000-tons biomass.

The Marine Donut is a closed farming in the end of production cycle. It has a robust closed concept that protects fish from sea lice and other pathogens, and certified for up to a three-meter wave height. It also has a flow concept of exercising fish for improved quality and fish welfare.

The Ship is closed system farming in tanks. It is escape-proof and protects fish from sea lice and other pathogens. The re-use of obsolete ships gives a good environmental footprint.

“We also intend to test out possibilities to widen the area of fish farming, by enabling farming in rougher conditions in more open seas. Systems like submersible sea-pen, which can be lowered during the roughest weather, are interesting. If successful, it could potentially open up new areas for farming with less risk of negative impact,” Trond said.

Marine Harvest is currently testing the third batch of fish in the semi-closed floating facility of the 21,000-m3, Neptun, which is helping them develop more sustainable production regimes.

With their sights on leading the Blue Revolution, Marine Harvest is continuing to improve their operations and aiming to obtain ASC certification on all their farms by 2020.

“Our vision is to lead the Blue Revolution. This means that we aim to be at the forefront in growing food from the ocean in a socially and environmentally responsible way, and ensuring our operations do not leave a lasting footprint,” he said.

The ocean covers 70 percent of the world’s surface but accounts for two percent only of global food supply.

The footprint focus area aims to support this separation by working on the programs run by their department, specifically sea lice control, medicine use, Aquaculture Stewardship Council (ASC) implementation, and escape management and control.

ASC is an important tool in Marine Harvest’s sustainability approach. “Our goal is to become 100-percent ASC certified by 2020. We contribute to the realization of this goal by providing technical support to facilitate the global implementation of the ASC standard,” he said. This includes running global training sessions, sharing knowledge and experience through global networks, and through active participation in the standards taskforce of the Global Salmon Initiative.

Undertaking R&D projects will facilitate and make ASC implementation more effective. This includes the development of new methods for faster and more environmentally friendly benthic monitoring and the development of new anti-fouling strategies.